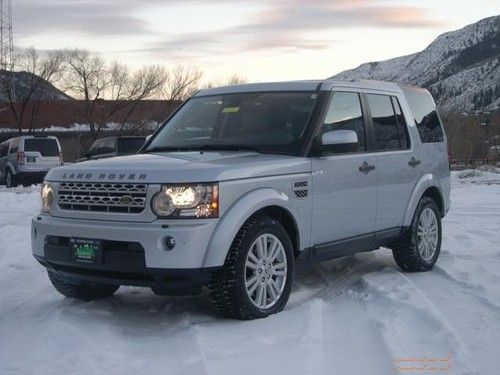

2012 Lard Rover Lr4 / 16k Mi / Harmon/kardon Sound / Bluetooth /102pt Inspection on 2040-cars

Broomfield, Colorado, United States

Vehicle Title:Clear

For Sale By:Dealer

Engine:5.0L 5000CC V8 GAS DOHC Naturally Aspirated

Body Type:Sport Utility

Fuel Type:GAS

Make: Land Rover

Warranty: Unspecified

Model: LR4

Trim: Base Sport Utility 4-Door

Doors: 4 doors

Drive Type: 4WD

Engine Description: 5.0L DOHC SMPI 32-VALVE A

Mileage: 16,789

Sub Model: 4WD 4dr

Number of Cylinders: 8

Exterior Color: Silver

Interior Color: Almond

Land Rover LR4 for Sale

Leather navigation sunroof 3rd row seat push button start off lease only(US $36,999.00)

Leather navigation sunroof 3rd row seat push button start off lease only(US $36,999.00) Hse pkg includes nav rear camera aid 7 seater

Hse pkg includes nav rear camera aid 7 seater 7 seater hse pkg upgraded audio and balance of factory warranty

7 seater hse pkg upgraded audio and balance of factory warranty Hse plus navigation camera sat ipod usb bluetooth leather heated seats lcl trade(US $38,995.00)

Hse plus navigation camera sat ipod usb bluetooth leather heated seats lcl trade(US $38,995.00) 2012 land rover lr4 hse suv multiple sunroof alloy wheels salavge rebuilable

2012 land rover lr4 hse suv multiple sunroof alloy wheels salavge rebuilable 2011 used 5l v8 32v 4wd suv premium(US $44,993.00)

2011 used 5l v8 32v 4wd suv premium(US $44,993.00)

Auto Services in Colorado

Volvo Specialists Svc ★★★★★

The 4Wheeler ★★★★★

Spec-Wheels of America ★★★★★

Six Stars Auto Service ★★★★★

Simpson Brothers Garage ★★★★★

Santos Muffler Auto ★★★★★

Auto blog

Jaguar Land Rover may build factory in Saudi Arabia

Tue, 11 Dec 2012The Middle East is one of the fastest-growing markets for Land Rover, so it makes sense that the automaker is looking to set up shop in the region. According to Automotive News, Jaguar Land Rover is in talks with the people of Saudi Arabia to build a factory in the country at an expected initial cost of $1.2 billion. Still in the early stage of talks, the proposed facility could start up by 2017 using locally sourced materials such as steel and aluminum.

Such an arrangement could be beneficial for both entities as Saudi Arabia looks to diversify its oil-reliant economy and Land Rover could get local production capacity of around 50,000 units. The report also says that the agreement talks about the possibility for Jaguar models to be built at the same plant further down the road.

This won't be the first vehicle produced in Saudi Arabia - that honor goes to the KSU Gazal-1 - but it will be the first from a major global automaker.

Jaguar Land Rover offers (some) detail about new Ingenium engine

Thu, 10 Jul 2014Jaguar Land Rover officially announced its Ingenium family of engines with the unveiling of the 2.0-liter version in the Jaguar XE concept at the 2014 Geneva Motor Show, but it kept details very thin at the time. All we knew was that the new turbocharged mills could be configured to use gasoline or diesel, and be positioned longitudinally or transversely. Months later, JLR is finally letting some more info slip about its new baby, but there are still some big questions to be answered.

For the Ingenium project, Jaguar Land Rover gave its engineers a clean sheet of paper and told them not to worry about using any previous parts or machinery. In the end, the designers came up with a family of turbocharged, aluminum-block engines based around modular, 500cc cylinders to allow it to grow or shrink as the market demanded. The layout was also made adaptable enough to incorporate hybrid drivetrains, if needed. "Being configurable and flexible are the two key strands of Ingenium's DNA because we have future-proofed our new engines from the outset," said said Ron Lee, the company's director of Powertrain Engineering.

To maximize efficiency, Jaguar promises that all versions of the Ingenium engines come with computer-controlled, variable oil pumps and water pumps to use only as much energy as needed. They also get direct injection, roller bearings for the cams and stop/start. The diesel version alone has 17 percent less internal friction than the mill it replaces, the company claims. JLR is also promising class-leading figures for Ingenium's torque and horsepower too, but it's not giving away those specs just yet.

Jaguar opens new engine plant in the UK

Thu, 30 Oct 2014The heads of Jaguar Land Rover are having a busy couple of weeks opening factories. Just days after inaugurating the company's first overseas plant in China, the automaker's new Engine Manufacturing Center in the UK is being inaugurated, as well. The plant near Wolverhampton, England, marks the first time in decades that JLR is building its own powerplants in-house. Further signaling the importance of this launch for the business, Queen Elizabeth II and Prince Philip were on hand and even tweeted about it.

The factory's first major project is to build JLR's latest Ingenium four-cylinders, starting with the 2.0-liter diesel version. "Our new Engine Manufacturing Centre is an important step in advancing the competitiveness and capability of the UK automotive sector. The production of in-house engines will support the expansion of the UK supply chain providing critical mass for inward investment," said Trevor Leeks, plant operations director in the automaker's announcement.

Opening the doors to the Engine Manufacturing Center has been years in the making for JLR. The plant was first announced in September 2011 and broke ground in June 2012. Building it cost the company 500 million pounds ($800 million) and created 1,400 new jobs. Of course, being a state-of-the-art factory, considerations were made to make the place as energy efficient as possible. That meant installing the UK's largest solar array with 21,000 panels to produce about 30 percent of the site's electricity needs.